1.Nderipi basa rechimwe nechimwe chiri mudhaimondi saw blade matrix binder?

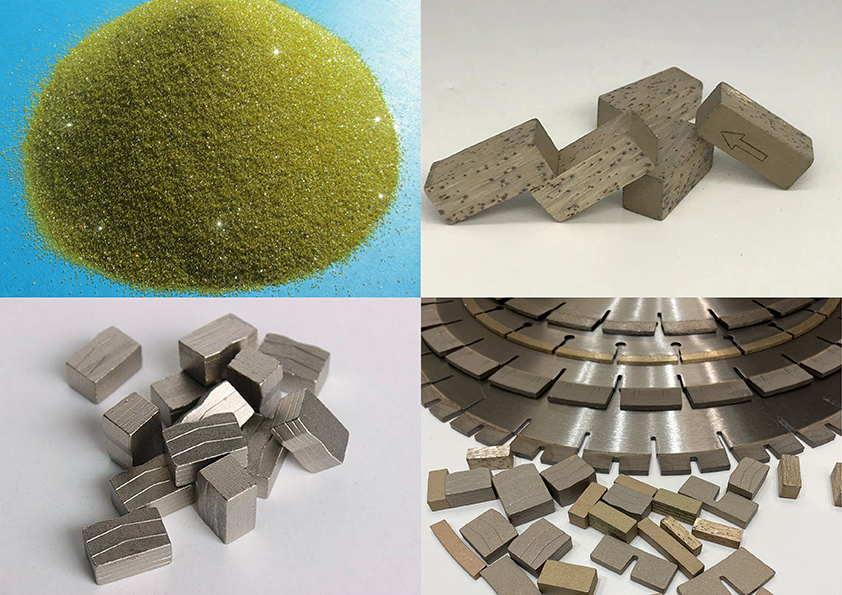

Basa remhangura: Mhangura nemhangura yakavakirwa alloys ndidzo simbi dzinonyanya kushandiswa musimbi binder diamond maturusi, ine electrolytic copper poda iri iyo inonyanya kushandiswa.Mhangura nemhangura yakavakirwa maalloys anoshandiswa zvakanyanya nekuti mabhii emhangura ane zvinogutsa akazara zvivakwa: yakaderera sintering tembiricha, yakanaka formability uye sinterability, uye miscibility nezvimwe zvinhu.Kunyangwe mhangura isinganyanyise madhaimondi, zvimwe zvinhu uye alloys emhangura zvinogona kuvandudza zvakanyanya kunyorova kwavo kumadhaimani.Chimwe chezvinhu zvakadai seCr, Ti, W, V, Fe iyo inoumba mhangura uye carbides inogona kushandiswa kugadzira alloys emhangura, iyo inogona kuderedza zvakanyanya kunyorova kwekona yemhangura alloys pamadhaimondi.Solubility yemhangura musimbi haina kukwirira.Kana paine mhangura yakawandisa musimbi, inoderedza zvakanyanya kupisa kwekushanda uye inokonzera kuputika kwezvinhu.Mhangura inogona kugadzira akasiyana akasimba mhinduro ine nickel, cobalt, manganese, tini, uye zingi, kusimbisa iyo matrix simbi.

Basa retin: Tin chinhu chinodzikisira kutekenyera kwepamusoro kwearoyi emvura uye chine mhedzisiro yekudzikisa kona yekunyorova yearoyi emvura pamadhaimani.Icho chinhu chinonatsiridza kunyorova kwesimbi dzakasungwa pamadhaimani, inoderedza kunyungudika kwealloys, uye inovandudza kuumbwa kwekutsikirira.Saka Sn inoshandiswa zvakanyanya mukunamira, asi kushandiswa kwayo kunogumira nekuda kweiyo yakakura yekuwedzera coefficient.

Basa rezinc: Mumidziyo yedhaimondi, Zn neSn vane zvakawanda zvakafanana, senge yakaderera kunyungudika uye yakanaka deformability, nepo Zn haina kunaka pakushandura kunyorova kwedhaimondi seSn.Iyo vapor pressure yesimbi Zn yakakwira zvakanyanya uye iri nyore kuita gasify, saka zvakakosha kutarisisa huwandu hweZn hunoshandiswa mumadhaimondi maturusi binders.

Basa realuminium: Metal aluminum isimbi yakanakisa yakareruka uye yakanaka deoxidizer.Pa800 ℃, kona yekunyorova yeAl padhaimani i75 °, uye pa1000 ℃, kona yekunyorova i10 °.Kuwedzera aluminium poda kune binder yedhaimani maturusi anogona kugadzira carbide chikamu Ti Å AlC uye intermetallic compound TiAl mune matrix alloy.

Basa resimbi: Iron ine basa rembiri mubhainda, imwe ndeyekugadzira carburized carbides nemadhaimondi, uye imwe ndeye alloy nezvimwe zvinhu kusimbisa matrix.Kunyorova kwesimbi nedhaimani kuri nani pane kuya kwemhangura nealuminium, uye basa rekunamatira pakati pesimbi nedhaimani rakakwirira kudarika recobalt.Kana huwandu hwakakodzera hwekabhoni hwanyungudutswa muFe based alloys, zvichave zvinobatsira pakubatana kwavo nemadhaimani.Kuiswa pakati nepakati kwemadhaimani neFe based alloys kunogona kuwedzera simba rekubatanidza pakati pechisungo nedhaimani.Iyo yekutsemuka kwepamusoro haina kutsvedzerera uye isina kushama, asi yakafukidzwa neyakagadzika yealloy, inova chiratidzo chekuwedzera kubatanidza simba.

Basa recobalt: Co naFe ndeyezvikamu zveboka rekuchinja, uye akawanda maitiro akafanana.Co inogona kuumba carbide Co ₂ C nedhaimani pasi pemamiriro ezvinhu, ukuwo ichiparadzira firimu rakatetepa recobalt pamusoro pedhaimondi.Nenzira iyi, Co inogona kudzikisa kupindirana kwemukati kwemukati pakati peCo nedhaimani, uye ine yakakosha basa rekunamatira kudhaimondi muchikamu chemvura, ichiita yakanakisa yekubatanidza zvinhu.

Basa renickel: Mubhainda rematurusi edhaimani, Ni chinhu chakakosha.MuCu based alloys, kuwedzera kweNi kunogona kunyungudika neCu, kusimbisa matrix alloying, kudzvanyirira yakaderera kunyungudika kurasikirwa kwesimbi, uye kuwedzera kuoma uye kupfeka kuramba.Kuwedzera Ni uye Cu kune Fe alloys kunogona kudzikisa tembiricha yekupisa uye kuderedza kupisa kwekupisa kwesimbi dzakasungwa pamadhaimani.Kusarudza musanganiswa wakakodzera weFe neNi unogona kuvandudza zvakanyanya simba rekubata reFe based binders pamadhaimondi.

Basa remanganese: Mumasimbi anosungira, manganese ine mhedzisiro yakafanana nesimbi, asi ine simba rekupinza uye deoxygenation kugona, uye inogara kune oxidation.Huwandu hwekuwedzera hweMn kazhinji hauna kukwirira, uye chinonyanya kutariswa ndechekushandisa Mn ye deoxidation panguva yekuisa alloying.Iyo Mn yakasara inogona kutora chikamu mukubatanidza uye kusimbisa matrix.

Basa rechromium: Metal chromium chinhu chakasimba che carbide-forming element uye zvakare chinhu chinoshandiswa zvakanyanya.Mudhaimondi groove saw blade matrix, pane chromium yakakwana kuti ive neruzha rwekudzikamisa mhedzisiro, ine chekuita ne activation simba reCr.Kuwedzera hushoma hweCr kuCu based matrix kunogona kuderedza kunyorova kwekona yemhangura yakavakirwa alloy kudhaimani uye kunatsiridza kusimba kwekubatanidza kwemhangura yakavakirwa alloy kune diamond.

Basa retitanium: Titanium chinhu chakasimba che carbide kugadzira chinhu chiri nyore kuita oxidize uye chakaoma kudzikisa.Muhupo hweokisijeni, Ti inonyanya kugadzira TiO2 panzvimbo yeTiC.Titanium simbi yakanaka yekugadzira zvinhu zvine simba rakasimba, kushomeka kwesimba pakudzikisira kwepamusoro, kupisa kupisa, kusaita ngura, uye nzvimbo yakakwira yekunyungudika.Tsvagiridzo yakaratidza kuti kuwedzera huwandu hwakakodzera hwetitanium kune diamond saw blade matrix inobatsira pakuvandudza hupenyu hwebasa resaha.

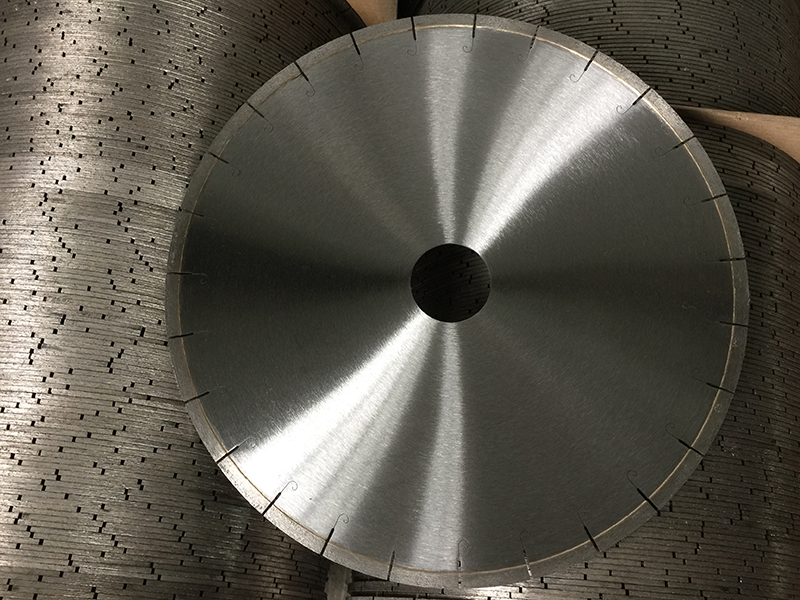

2.Sei mutumbi wesaha uchifanira kufanana nedombo rekuchekwa?

Nzira huru dzekutsemuka kwedombo panguva yekucheka blade yekucheka maitiro ndeyekutsemuka uye kupwanya, pamwe nehombe vhoriyamu shear uye kupatsanurwa, inowedzerwa nekukuya pamusoro.Dhaimondi rine serrated yekushanda nzvimbo inoshanda semudziyo wekucheka.Kucheka kwayo ndiyo nzvimbo ye extrusion, nzvimbo yekucheka iri pamberi pemucheto, uye nzvimbo yekukuya iri kumucheto kumashure.Pasi pekucheka-kumhanya-mhanya, madhaimondi particles anoshanda parutsigiro rwematrix.Munguva yekucheka dombo, kune rumwe rutivi, dhaimondi rinopinda graphitization, kupatsanurwa, uye dhizaini nekuda kwekupisa kwakanyanya kunogadzirwa nekukwesha;Kune rumwe rutivi, matrix inopfekwa nekukweshana uye kukukurwa kwematombo nehupfu hwedombo.Naizvozvo, iyo nyaya yekuchinjika pakati pemasaha blades nematombo ndiyo inyaya yekupfeka mwero pakati pedhaimani nematrix.Hunhu hwechishandiso chinoshanda zvakajairwa ndechekuti kurasikirwa kwedhaimondi kunofanana nekupfeka kwematrix, kuchengetedza dhaimondi riri munzvimbo yakajairwa yekucheka, kwete kukurumidza kukurumidza kana kutsvedza uye kutsvedza kwedhaimondi, kuve nechokwadi chekuti kugaya kwayo kunoshandiswa zvizere. panguva yekushanda, zvichiita kuti madhaimondi akawanda ave mune imwe nzvimbo yakatsemuka uye yakasakara.Kana simba uye kukanganisa kupikisa kwedhaimondi yakasarudzwa zvakanyanya kuderera, zvinotungamirira kune chiitiko che "kuveura", uye hupenyu hwechishandiso huchava hwakaderera uye passivation ichave yakaoma, uye kunyange sawing haizofambi;Kana yakanyanyisa yakakwirira simba abrasive particles inosarudzwa, chidimbu chekucheka chezvinyorwa zvinoputika zvichaonekwa mumamiriro ekugadzirisa, zvichiita kuti kuwedzerwa kwesimba rekucheka uye kuderera kwekugadzirisa kushanda.

(1) Kana kumhanya kwekupfeka kwematrix kwakakura kupfuura iyo yedhaimondi, zvinotungamira mukuchekwa kwedhaimani zvakanyanya uye kumiswa nguva isati yakwana.Kupfeka kupikisa kwemuviri wesaha kwakadzikira, uye hupenyu hwesaha hupfupi.

(2) Kana kumhanya kwekupfeka kwematrix kuri kushoma pane kwedhaimondi, dhaimondi idzva hariburitswe zviri nyore mushure mekunge dhaimondi rekucheka rapfekwa, serrations haina kucheka kana kuchekwa kwakadzikira, pamusoro iyo serrations inopfuudzwa, kasi yekucheka inononoka, uye zviri nyore kuita kuti bhodhi rakachekwa riwire pasi, richikanganisa kunaka kwekugadzirisa.

(3) Kana kumhanya kwekupfeka kwematrix kwakaenzana nekupfeka kwedhaimani, inoratidza kuenderana kwematrix nedombo rakachekwa.

Nguva yekutumira: Aug-11-2023