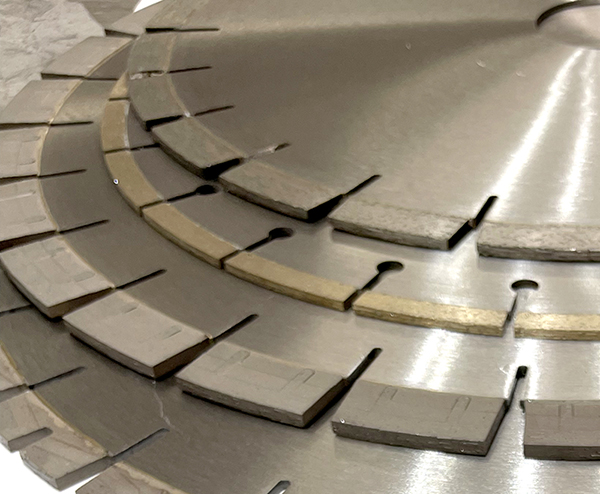

Diamond akaona blade, a multi blade chishandiso chinowanzoshandiswa kucheka bhiriji aluminium, acrylic, uye dombo.Munhoroondo yose yekucheka simbi, kubuda kwedhaimondi saw blades kwakabhadhara zvinobudirira kukanganisa kwakawanda kweakaoma alloy saw blades uye kabhoni simbi saw blades.

Yakanakisa yekucheka mashandiro ndiwo mukana wekuzvarwa wedhaimondi saw blades, uye nekuda kwekushandiswa kweakaoma uye anodzivirira kupisa edhaimani akaona mazino, hupenyu hwemadhaimani saw blades zvakare zvakareba kwazvo.

Kuenzaniswa neakajairwa hard alloy saw blades, hupenyu hwemadhaimani saw blades kazhinji hurefu hwemwedzi yakati wandei.Ehe, pane zvinhu zvakawanda zvinokanganisa hupenyu hwemasaha blades.

Pamusoro pemhando yesaha pachayo, mukuita chaiko kwekugadzira, kushandiswa kwedhaimondi saw blades uye kana mashandiro emushandisi akamisikidzwa, pamwe nekudzika uye mutsara kumhanya kwechikafu, kuchakanganisa hupenyu hwesevhisi. chipande chedhaimani.

Parizvino, kune nzira ina dzinowanzoshandiswa pakugadziramashizha edhaimani, kusanganisira kutonhora kudzvanya sintering nzira, inopisa kudzvanya welding nzira, rolling nzira, uye mazino embedding nzira.

Method 1: Cold kudzvanya sintering nzira

Iyo dhayamondi yedhaimani saw blades inogadzirwa neinotonhora yekutsikirira sintering nzira inowanzo iri pasi pe400 millimita nekuda kwekushomeka kwekugadzira tekinoroji.

Zvichakadaro, iyo inotonhora yekutsikirira sintering nzira ine mukana wemutengo wakaderera wekugadzira, kunyanya kune mamwe akanyorova masaha.Mukugadzira maitiro, iyo inotonhora yekutsikirira welding nzira inowanzoshandiswa.

Thechipande chedhaimanikushandisa iyi nzira yekugadzira kazhinji inovimbisa kushanda kwakagadzikana kana uchicheka maprofile akaoma senge granite, yakasanganiswa ivhu rakaoma, asphalt, nezvimwe.

Method 2: Hot press welding nzira

Kune mabhizinesi anogadzira madhaimondi saw blades, kuitira kuti ave nechokwadi chekugadzirwa kwakadzikama, vanowanzo sarudza nzira yekupisa yekupisa welding parizvino.

Iyi nzira yekugadzira madhaimani saw blades parizvino ndiyo inonyanya kufarirwa nzira.Zvichakadaro, zvichienzaniswa neinotonhora yekutsikirira welding nzira, iyi nzira yekugadzira inogona kuburitsa madhaimani masaha ane dhayamita yakakura.

Iyo dhayamita renji inowanzova pakati pe350 millimeters uye 2200 millimeters, uye mamwe mahombe ediamond saw blades, seaya anoshandiswa kucheka matombo, anoshandisa maitiro aya mukugadzira.Iwo ekutanga ekugadzira maitiro anosanganisira kusanganisa, kupisa kupisa sintering, arc kugaya, welding, uye kucheka.

Method 3: Rolling nzira

Diamond akaona mashizhainogadzirwa nenzira yekutenderedza ine mutengo wakaderera wekugadzira, uye madhaimondi akaona mablades anogadzirwa neiyi nzira yekugadzira anowanzo shandiswa pakuona zvinhu zvakaita sewachi, matombo anokosha, mabheji, nezvimwe.

Dhaimondi remasaha rinogadzirwa uchishandisa nzira iyi rinowanzo gadzirwa nesimbi, ine dhayamita iri pakati pe80-120 millimeters uye ukobvu huri pakati pe0.2-0.4 millimeters.

Nzira 4: Gear Insertion Method

Sezvinoratidzwa nezita racho, iyo inlay nzira ndeyekuisa dhaimondi sawtees pachigaro chezino chesaha blade substrate.Iyo dhaimondi yakaona blade inogadzirwa neiyi nzira yekugadzira yakatetepa, nemasawteeth achioneka asingaenderere mberi mudenderedzwa rekunze uye akadzikwa zvakasimba muvhiri revhiri.Kucheka kwakapinza uye machipisi ari nyore kubvisa.

Panguva imwecheteyo, zvakanakira kushandisa iyi nzira yekugadzira yemasaw blades ndeyepamusoro yekucheka kunyatsoita, yakaderera kurasikirwa kwezvinhu, uye kugona kucheka zvinhu zvitete.Izvi zvinodaro nekuti mukuwedzera kune munda wematombo, masaha anogadzirwa uchishandisa iyi maitiro anoshandiswawo mualuminium profil processing field.

Parizvino, zvisinei nemaitiro ekugadzira anoshandiswa, anogona kunyatso simbisa mhando yedhaimani saw blades uye kucheka profiles.Kana zvasvika kune maprofiles ealuminium, nekuda kweiyo yepamusoro yekugadzira maitiro, iyo yekucheka kuita kwesaha blade yakanaka kwazvo.

Mukuwedzera, nekuda kweakanakisa simbi yekucheka maitiro emashizha edhaimani, vanogona kudzokororwa kuvhuvhuta zvakanyanya.

Kuenzaniswa neyakajairwa yakaoma alloy saw blades anogona chete kukwenenzverwa 1-2 nguva muhupenyu,mashizha edhaimaniinogona kukwenenzverwa 6-8 nguva muhupenyu.Kune mabhizinesi, zvinoreva kutora nzira yekukuya, iyo inogona kuchengetedza mari yakawanda yemutengo.

Nguva yekutumira: Zvita-14-2023