1, Chii chinonzi ablade yediamond denderedzwa

Diamond denderedzwa saw bladechinhu chinowanzo shandiswa kucheka, inova blade yesaha ine dhaimondi rekucheka rinowanikwa mukati kana kunze kwedenderedzwa resaha.Inoshandiswa zvakanyanya mukugadzirisa zvinhu zvakaoma uye zvinoputika zvakadai sematombo uye ceramics.Dhaimondi rakaona blade rinonyanya kuve nezvikamu zviviri: substrate uye blade.Iyo substrate ndiyo inonyanya kutsigira chikamu cheadhesive blade, nepo blade iri chikamu chekucheka chinotanga panguva yekushandiswa.Iyo blade icharamba ichidya panguva yekushandiswa, nepo substrate isingaite.Diamond particles akaputirwa nesimbi mukati memusoro wekucheka, iyo inobata basa rekucheka mukukweshana kwekucheka kwechinhu chakagadziriswa panguva yekugadzira machining.Panguva yekushandiswa, iyo simbi matrix nedhaimani zvinopedzwa pamwechete.Inowanzo yakanakira iyo simbi matrix kuti ipedze nekukurumidza kupfuura dhaimani, iyo inovimbisa zvese kupinza kwemusoro wekucheka uye hupenyu hwebasa remusoro wekucheka.

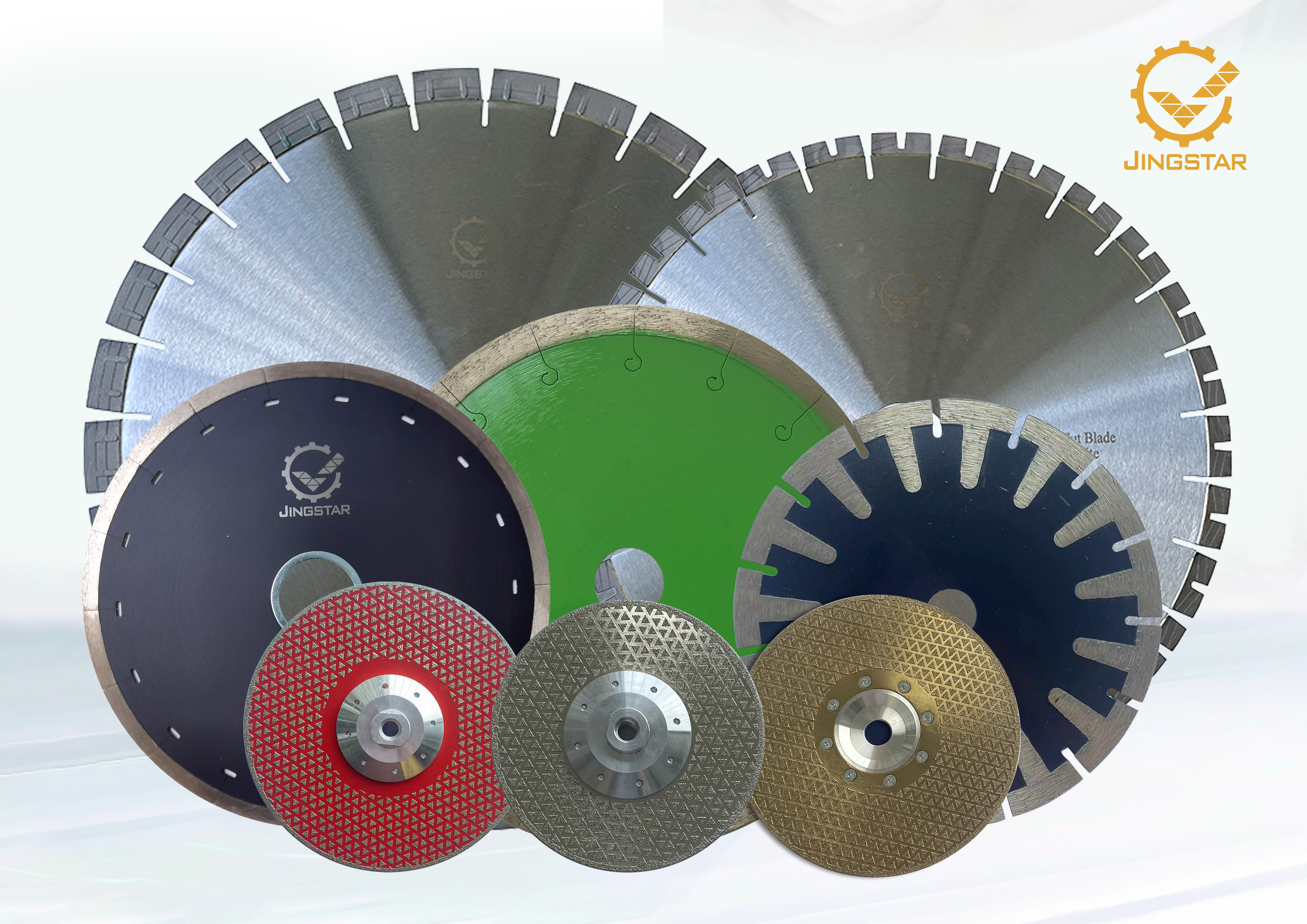

Iyo dhayamita span yediamond denderedzwa masahaihombe, ine mapanga ekuveza emamirimita anoverengeka uye masaha makuru emamita anoverengeka muhupamhi.Kunewo zvinhu zvakawanda zvekucheka, uye chimiro, kuoma, uye kukura kwezvinhu zvekucheka zvinosiyana zvikuru.Naizvozvo, magadzirirwo avo uye nzira dzekugadzira, zvigadzirwa zvinoshandiswa, uye zvinodiwa zvekushandisa zvese zvakasiyana.

2, Kurongwa kwediamond denderedzwa masaha

Diamond denderedzwa saw bladepari zvino ndiyo inonyanya kushandiswa kushandiswa kwemasaha muindasitiri yematombo yeChina, iyo inowanzoita denderedzwa muchimiro.Inoshandisa nzira dzakadai seupfu simbi kana electroplating kunyudza madhaimondi akatenderedza substrate.Kushandisa iyo yakakwirira simba uye kuoma kwedhaimani zvimedu kugera uye kupwanya zvimwe zvinhu zvekucheka zvinangwa.Kune marudzi akawanda ediamond denderedzwa masahauye kupatsanurwa kwavo kwakaomawo.Kazhinji pane nzira dzakawanda dzekugadzirisa:

1. Kurongwa nekugadzira maitiro:

(1) Chipenga chesaha yedhaimani

Kune mhando mbiri dze sintering: inotonhora press sintering uye inopisa sintering.

(2) Welding diamond saw blade

Kune marudzi maviri ebrazing uye Laser beam welding.Brazing ndeye kubatanidza musoro wekucheka uye substrate pamwe chete kuburikidza nekushisa kwakanyanya kunyunguduka, senge yakakwira-frequency induction brazing saw blade, vacuum brazing saw blade, nezvimwe;Laser welding inoshandisa yakakwira tembiricha laser beam kunyungudutsa musoro wekucheka uye yekubata mupendero weiyo substrate kuumba metallurgical bonding.

(3) Electroplated diamond saha blade

Ndiyo nzira yekubatanidza blade poda kune substrate kuburikidza ne electroplating.Nekudaro, nekuda kwekusvibiswa kwakanyanya, nyika iri kubvisa zvishoma nezvishoma iyi nzira ye electroplating.

2. Kurongwa nekugadzirisa chinhu:

Marble cutting saw blade, granite cutting saw blade, kongiri yekucheka saw blade, nezvimwe.

3. Kurongwa nechitarisiko:

Kuenderera mberi kumucheto saw blades, blade type saw blades, turbine type saw blades, etc. Chokwadi, nzira yekuisa pamusoro apa haigone kusanganisira zvese.diamond denderedzwa masaha, uye kunewo zvakawanda zvakakosha zvinangwadiamond denderedzwa masaha.Sarudza marudzi akasiyana-siyana edhaimondi saw blades yekugadzirisa zvinhu zvakasiyana.

3, Hunhu hunokosha hweblade yediamond denderedzwakucheka

Circular saw blade yekucheka ine zvakanakira kushanda kuri nyore, kushanda kwakanyanya, uye kunaka kwekugadzirisa mhando.Asi ruzha rwakanyanya uye kusimba kweblade hakuna kunaka.Panguva yekucheka, blade yesaha inogara ichidedera uye kutsauka, zvichikonzera kusaenzana kweiyo workpiece kutemwa.

4, Zvinhu zvinokanganisa kushanda uye hupenyu hwediamond denderedzwa masaha

Zvinhu zvinokanganisa kushanda uye hupenyu hwediamond denderedzwa masahasanganisira kucheka maparamendi, giredhi redhaimani, saizi yechidimbu, kutarisisa, uye kuoma kwebhondi.

1. Sawing parameters

(1) Saw cutting speed

Mukushanda basa, mutsara wekukurumidza wediamond denderedzwa masahainoganhurirwa nemamiriro emidziyo, kunaka kweblade yesaha, uye zvimiro zvedombo riri sawn.Mukutaura kwehupenyu hwebasa uye kucheka kwekucheka kwejecha resaha, mutsara wemutsara weiyo blade yesaha inofanira kusarudzwa zvichienderana nemaitiro ematombo akasiyana.

(2) Kudzika kwesahwi

Mukati meiyo inotenderwa yemhando yekushanda kwemuchina uye simba rekushandisa, yakakura yekucheka yakadzika inofanirwa kusarudzwa zvakanyanya sezvinobvira kuti uvandudze kucheka kunyatsoita.Kana pane zvinodiwa zvemakina epasi, kudzika kudiki kucheka kunofanira kushandiswa.

(3) Kudya nokukurumidza

Mafeed speed ndiwo mafeed speed edombo riri kuchekwa.Kukosha kwayo kunofanira kusarudzwa zvichienderana nehupfumi hwebwe rakacheka.Kazhinji, kuona matombo akapfava, akadai semarble, anogona kuwedzera kudzika kwekuchekesa uye kuderedza kukurumidza kwekudya, izvo zvinonyanya kubatsira mukuvandudza mwero wekucheka.Sawing yakanaka-grained uye ine homogeneous granite inogona kuwedzera kukurumidza kwekudya zvakakodzera.Kana kukurumidza kwekudya kwakadzikira, blade yedhaimani inogadzika nyore nyore.Nekudaro, kana uchicheka giraniti ine yakakasharara zviyo chimiro uye kuomarara kusingaenzaniswi, kumhanya kwekucheka kunofanirwa kudzikiswa, zvikasadaro zvinokonzeresa kuti blade yesaha izununguke uye kukonzera kupatsanuka kwedhaimondi, nekudaro ichidzikisa mwero wekucheka.

2. Diamond particle size

Iyo inowanzo shandiswa diamond particle size inotangira pa30/35 kusvika 60/80 mesh.Iyo yakaoma dombo, iyo yakatsetseka iyo particle size inofanira kusarudzwa.Nokuti pasi pemamiriro ekumanikidzika akafanana, iyo dhaimondi yakaisvonaka, inopinza, iyo inobatsira pakucheka mumatombo akaoma.Pamusoro pezvo, kazhinji dhayamita rakakura remasaha rinoda kucheka kwakanyanya, uye akaomesesa particle saizi senge 30/40 mesh uye 40/50 mesh inofanira kusarudzwa;Diki dhayamita saw blades ine yakaderera kucheka kunyatsoshanda uye inoda yakatsetseka dombo yekucheka zvikamu.Zvinokurudzirwa kusarudza akatsetseka particle size, senge 50/60 mesh uye 60/80 mesh.

3. Diamond concentration

Diamond concentration inoreva kuwanda kwekugoverwa kwedhaimondi mune inoshanda layer matrix.Zvinoenderana nemirairo, kuunganidzwa kwe4.4 carats edhaimondi pa cubic centimita yekushanda layer matrix i100%, uye kusangana kwe3.3 carats yedhaimondi i75%.Huwandu hwemadhaimondi hunomiririra huwandu hwedhaimani mubhuroka uye inotsanangura kuti iyo yekumisikidza iri 100% kana vhoriyamu yedhaimondi ichiverengera 1/4 yehuwandu hwehuwandu.Kuwedzera kuwanda kwedhaimondi kunotarisirwa kuwedzera hupenyu hwesaha blade, sezvo kuwedzera kusungirirwa kunoderedza avhareji yekucheka simba padhaimani.Asi kuwedzera kusungirirwa kunozowedzera mutengo wesaha, saka kune yakanyanya hupfumi yekumisikidza iyo inowedzera nekuwedzera kwekuita basa rekuona.

4. Kuoma kwekucheka musoro binder:

Kazhinji kutaura, iyo yakakwirira kuoma kwechisungo, kusimba kwayo kupfeka kuramba.Nokudaro, kana uchiona matombo ane abrasiveness yakakwirira, kuoma kwebhainda kunokwira nyore nyore;Pakuona matombo akapfava, kuoma kwebhainda kunofanira kunge kwakaderera;Paunenge uchiona matombo ane high abrasiveness uye kuoma, kuoma kwebinder kunofanira kuva pakati.

5, The Development Trend yeDiamond Circular Saw Blades

Diamond denderedzwa saw bladesndiwo maturusi makuru muindasitiri yekugadzira matombo.Mumakore achangopfuura, huwandu hwemadhaimani ekugadzira anoshandiswa muindasitiri yekugadzira matombo hwakakwira zvakanyanya, uye kushandiswa kwediamond denderedzwa masahairi kuwedzerawo.Pakazara, kuvandudzwa kwediamond denderedzwa masahazvese munyika nekunze zvine hunhu hunotevera: kugadzira mashizha esaha anoshanda uye emhando yepamusoro, uye kugadzira madhaimondi emhando yesaha;Teerera zvakanyanya kutsvagurudzo yehupfu, matrix, uye sintering maitiro;Nyatsoteerera tsvakurudzo pamusoro sawability uye sawing nzira yematombo zvinhu;Laser welding saw blade yakagadzirwa;Gadzira yakakuradiamond denderedzwa masaha.Parizvino, kushandiswa kwediamond denderedzwa masahairi kuramba ichipararira.Mune ramangwana, kutungamira kutungamira kwediamond denderedzwa masahandeye kuvandudza kushanda zvakanaka kwekucheka, hupenyu hwemasaha, kuderedza mitengo yekugadzira, uye zvakare kuwana kuchengetedza kwezvakatipoteredza.

Chirevo: "Daimondi uye Dhaimondi Zvishandiso Ruzivo Q&A" naZhang Shaohe naHu Yule

Nguva yekutumira: Aug-04-2023